VIPER X-Docking™ is a turnkey solution for automation freight sorting in courier cross-docking facilities using autonomous mobile robots and AI

Solution structure

Rubedos® VIPER X-Docking™ solution is a combination of hardware, software and services provided by Rubedos and our partners.

Solution software stack

- Fleet management

- Workflow control

- Robot control

- Equipment control

- Deployment tools

- Data analysis

Sensors and accessories

Partner's fitting robot platform

International service network

System partners

- Integration

- Adaptation

Cross-docking process explaned

In a typical courier cross-docking facility all incoming freight is unloaded from trailers into the inbound area where it soon gets picked up and cross-docked to the outbound area to be loaded and dispatched in time. The process might also include dimensioning and weighting steps.

Huge parametric variation

All courier cross-docking stations inherently face huge parametric variations in freight: by weight, size, pallet type, drop-off location, irregular shrink-wrapping, etc.

Solution software stack

Variable parameters

- Weight

- Size

- Pallet type

- Drop off position

- Film wrapping

etc.

Unknown location

- Pallet type and pick-up position

- Travel path and drop-off position

Variable off-hours pallet flow

Off-standard working hours (early AM shift and late PM shift) further make it increasingly hard to acquire and retain qualified working labour:

AM shift:

PM shift:

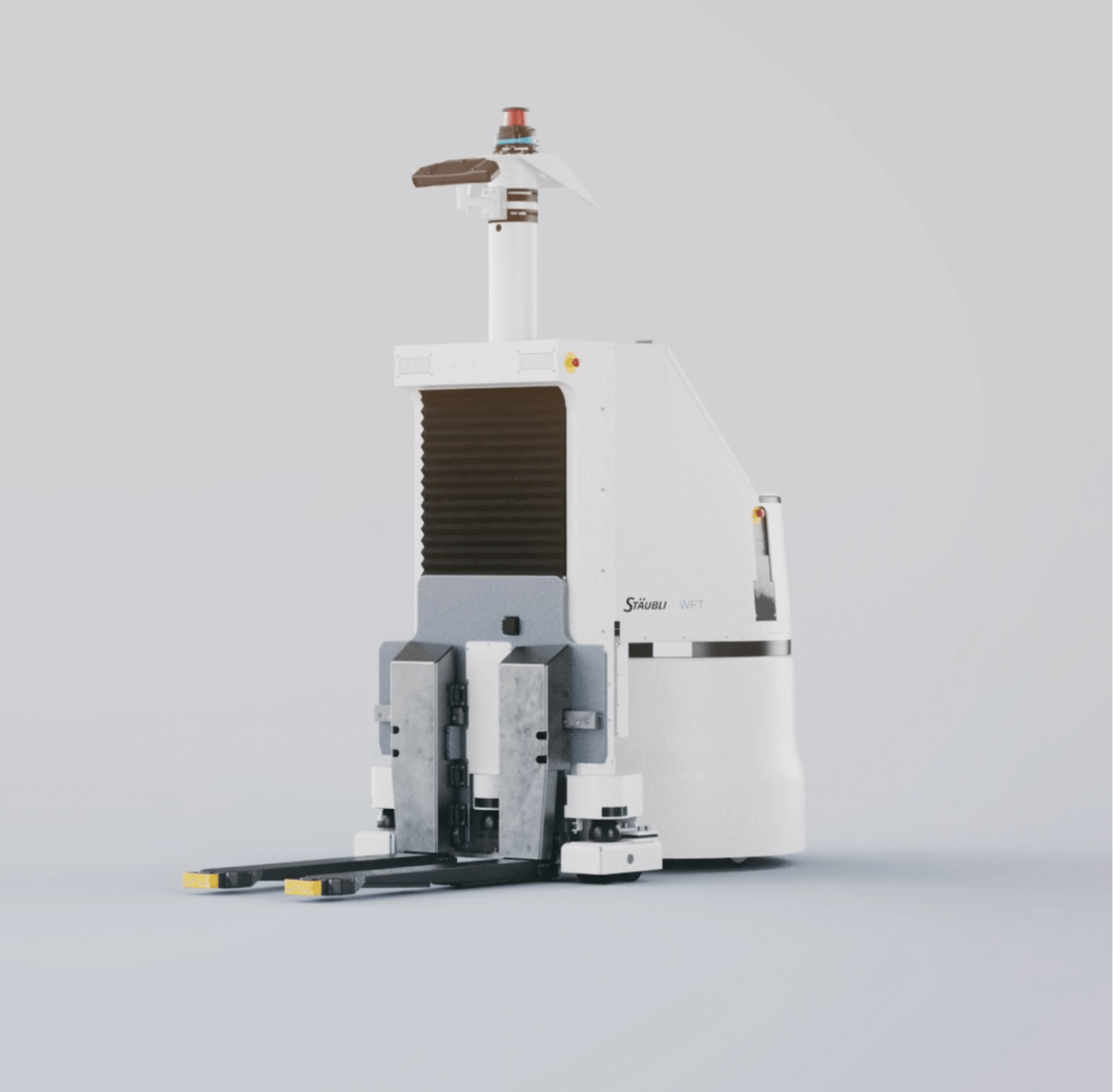

Platform details

In a state-of-art process, freight sorting relies on forklift drivers’ experience and ability to visually gauge and assess suitable pallets for immediate pickup. In our beyond-state-of-art cross-docking process freight sorting is performed by a fleet of autonomous mobile robots (AMRs). VIPER X-Docking™ solution utilizes our partner’s fitting robot platform, which has been modified with Rubedos® robot control software and additional sensing capabilities:

- Visual perception system with AI

- Ultra compact counterbalance lift truck

- High maneuverability

- High energy efficiency and robustness

- Auto-dock contact ecternal charging unit

- Payloads up to 400 kg

- Max fork length 1300mm

- Multiple pallet profiles

- Can drive on uneven surfaces

- Forklift safety blue-spotlight

- Safety lasers for human protection and collisions

Cost structure comparison

On average, the human operator (driver) accounts for 4/5 of the cost of operating a manual forklift, let alone accidents, damages and material handling process quality variation:

Benefits

Rubedos technology reduces the reliance on human forklift drivers and ensures accuracy and efficiency in handling a wide range of pallet types, including those that vary in size, weight, shape, and drop-off location. In addition to ‘simple’ material handling Rubedos can provide their customers with invaluable real-time intelligence about the freight as it progresses through the cross-docking process.

-

Non-disruptive to manual process

-

Elastic in response to labor shortage

-

Increased material traceability

-

Real-time insights on material flow

-

Less quality variation in operation

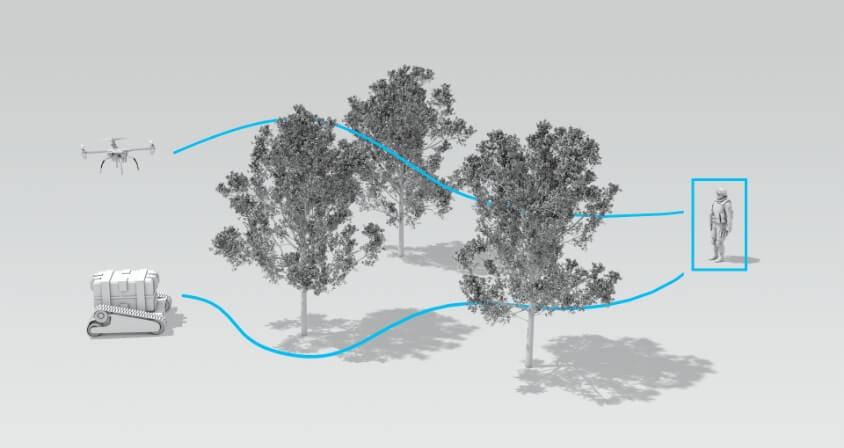

Safety

At Rubedos, safety and compliance are of utmost importance. Our track record of developing EU MDR and US FDA-compliant medical device products demonstrates our commitment to maintaining the highest industry standards, particularly in industries where precision, reliability, and safety is paramount.

Thank you! Let's work together